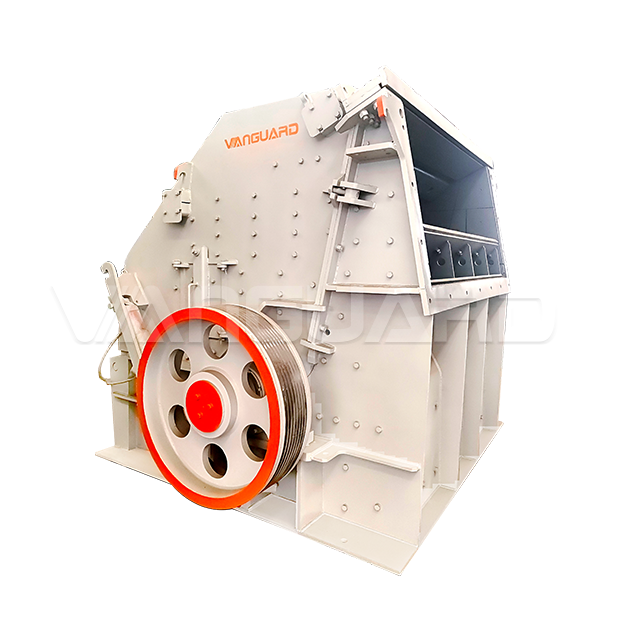

CI6X series impact crusher

Capacity:150-2000t/h

Feed size:0-1300mm

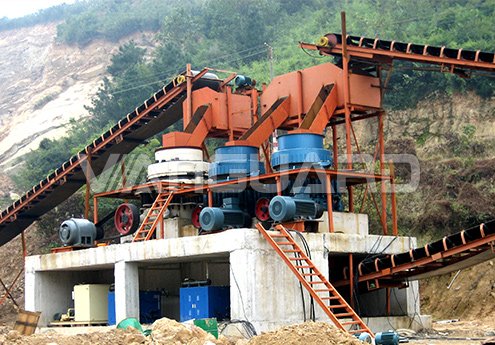

Application:Mining, smelting, building material, highway, railway, water conservancy and chemical industry, etc.

Overview

The CI6X series impact crusher is newly designed to meet customer needs for high profitability, low cost, energy saving and consumption reduction. It is ideal for coarse and medium crushing in large-capacity crushing production lines. The integrated application of scientific research results such as the large moment of inertia and high-precision rotor, the multi-functional fully hydraulic operating system, the involute-type high-efficiency crushing cavity, and the selection of wear-resistant materials for key components give the equipment higher crushing efficiency, simpler maintenance operation and more reliable performance.

Features

High crushing efficiency

The involute cavity design allows the material to hit the impact plate vertically, and the material returns to the material inlet in the plate hammer action area, increasing the number of hits, significantly improving the crushing efficiency, and providing a better discharge particle shape.

Craftsmanship

The heavy-duty rotor adopts an integral welding process, which has high precision and strong impact resistance, reducing current fluctuations during operation. The joint surface between the rotor lower frame and the bearing seat adopts an integral processing technology to ensure processing accuracy.

Hydraulic system

The multi-functional fully hydraulic operating system realizes fully hydraulic adjustment of discharge granularity and fully hydraulic opening of the top to replace wearing parts. The liner is fixed with high-strength bolts and can be directly replaced from the outside, reducing the labor and time costs of replacing the liner.

Easy to operate and maintain

The precise positioning device of the bearing seat reduces the difficulty of positioning the bearing seat during maintenance. The overall flat hammer design ensures reliable fixation and makes the disassembly and assembly of the blow bar more convenient and faster.

Specifications - Technical Data

| Model | CI6X1110 | CI6X1213 | CI6X1315 | CI6X1520 | CI6X1313 | CI6X1415 | CI6X1620 | CI6X2023 |

| Rotor specifications (mm) | 1100×1000 | 1200×1300 | 1300×1500 | 1500×2000 | 1300×1300 | 1400×1500 | 1600×2000 | 2000×2300 |

| Inlet size(mm) | 1020×820 | 1320×880 | 1540×930 | 2040×995 | 1320×1225 | 1540×1320 | 2040×1630 | 2310×1990 |

| Maximum feed size(mm) | 500(recommend≤250) | 550(recommend≤300) | 600(recommend≤300) | 700(recommend≤350) | 800(recommend≤550) | 900(recommend≤600) | 1100(recommend≤700) | 1300(recommend≤800) |

| Capacity (t/h) | 150-200 | 200-300 | 250-350 | 400-600 | 300-450 | 350-550 | 500-900 | 1200-2000 |

| Installed power(kW) | 160 | 200 | 250 | 250×2 | 200 | 250 | 200×2 | 500×2 |

| Power(kW) | 160-200 | 200-250 | 250-315 | 400-500 | 200-250 | 250-315 | 400-500 | 1000-1200 |

| Dimensions(mm) | 2626×2106×1945 | 2809×2529×2091 | 2880×2755×2560 | 3390×3520×2790 | 2963×2560×2611 | 2995×2790×3090 | 3485×3605×3720 | 4890×4330×4765 |

Solution

Thank you for your interest in Vanguard Machinery. If you want to know more about our crushers and industrial

grinding equipment.

Contact us now to find out what we can do for you!

Copyright © Zhengzhou VANGUARD Machinery Technology Co., Ltd.