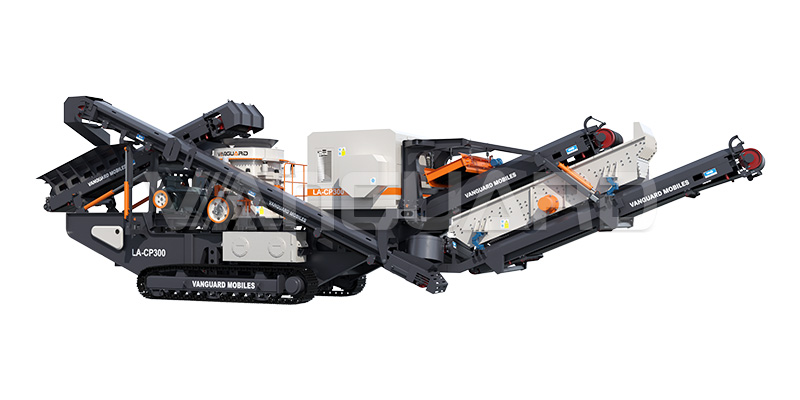

Crawler Type Mobile Cone Crushing Plant

Capacity:95-350T/H

Application:Medium and high hardness natural stone, mining crushing and construction waste recycling, etc.

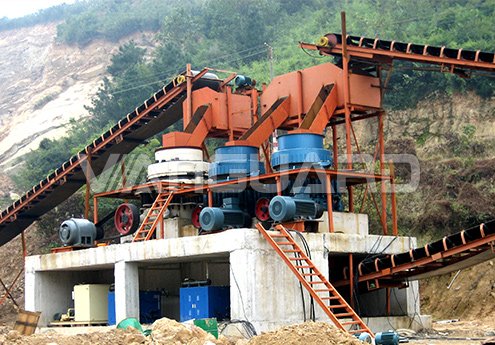

Video Case

Capacity:200 t/h

Max. Input size: ≤625mm

Output size: 05-20-31.5 mm

Processing materials: granite

Project advantages: Because of a small project site, Vanguard Machinery's engineers adopt a three-combination integrated design and multi-stage crushing process. The finished material has good particle shape and excellent grading, which can meet the demand for high-quality materials.

Overview

It integrates mechanical, hydraulic, electrical, automation, and other technologies, and it has many advantages such as high crushing efficiency, low production cost, convenient maintenance and adjustment, and excellent crushing product size. It is mainly used in secondary and tertiary crushing in metal mines and construction sand and stone processing. It is not afraid of narrow terrain and harsh environments, and it is the latest generation of products in the mining construction industry and metal mining industry.

Features

Equipped with a cone crusher with excellent performance suitable for medium and fine crushing, special crushing wall and concave design, supplemented by curved cavity and hydraulic cavity clearing system, improve the crushing efficiency and effectively reduce the easy operation loss.

It adopts a fully automatic crushing control system, which quickly responds to iron (overload) and automatically releases reset protection to ensure continuous, stable, and efficient production.

It is equipped with a PLC control system to keep full cavity continuous feeding, reasonable configuration, a smooth process, high production efficiency, good product shape, and the final product is a high-quality cube.

Large eccentricity, high swing frequency, and layer compression crushing make the equipment has a high capacity, large reduction ratio, and a good grain shape.

Specifications - Technical Data

-

CP200

-

CP300

-

CP400

| Crawler type mobile cone crushing plant | CP200 crawler type mobile cone crushing plant | |||

| Model | Items and specifications | power (kw) | Quantity(set) | |

| Crushing equipment | Equipment Model | CP200 | / | 1 |

| Return screen | Equipment | 1536 | / | 1 |

| Upper sieve conveyor | Specification | B1000*6m | 7.5 | 1 |

| Main conveyor | Specification | B1000*9m | 11 | 1 |

| Under the screen conveyor | Specification | B1000*6m | 7.5 | 1 |

| Transfer conveyor | Specification | B650*2m | 3 | 1 |

| Return conveyor | Specification | B500*9m | 5.5 | 1 |

| Dimensions(m)L×W×H | Working size17*4.8*4.1 | Transport size17*3.3*3.6 | ||

| Weight (t) | Single-power model:≈45t,Dual-power models:≈47t | |||

| Power (kw) | Single-power model: 200.62kw(not including walking engine power),Dual-power models: 200.32kw(not including generator set power) | |||

| Crawler type mobile cone crushing plant | CP300 crawler type mobile cone crushing plant | |||

| Model | Items and specifications | Power (kw) | Quantity(set) | |

| Crushing equipment | Equipment Model | CP300 | / | 1 |

| Return screen | Equipment | 1542 | / | 1 |

| Upper sieve conveyor | Specification | B1000*6m | 7.5 | 1 |

| Main conveyor | Specification | B1000*10.5m | 11 | 1 |

| Under the screen conveyor | Specification | B1200*6.2m | 7.5 | 1 |

| Transfer conveyor | Specification | B650*2m | 3 | 1 |

| Return conveyor | Specification | B500*11m | 5.5 | 1 |

| Dimensions(m)L×W×H | Working size18.5*4*5.1 | Transport size19.8*3.6*4 | ||

| Weight (t) | Single-power model:≈55t,Dual-power models:≈57t | |||

| Power (kw) | Single-power model: 264.1kw(not including walking engine power),Dual-power models: 264.1kw(not including generator set power) | |||

| Crawler type mobile cone crushing plant | CP400 crawler type mobile cone crushing plant | |||

| Model | Items and specifications | Power (kw) | Quantity(set) | |

| Crushing equipment | Equipment Model | CP400 | / | 1 |

| Return screen | Equipment | 1542 | / | 1 |

| Upper sieve conveyor | Specification | B1200*6.5m | 7.5 | 1 |

| Main conveyor | Specification | B1200*10m | 11 | 1 |

| Under the screen conveyor | Specification | B1200*6.2m | 7.5 | 1 |

| Transfer conveyor | Specification | B650*2m | 3 | 1 |

| Return conveyor | Specification | B500*11m | 7.5 | 1 |

| Dimensions(m)L×W×H | Working size19.5*5.1*4.9 | Transport size19.5*3.7*3.9 | ||

| Weight (t) | ≈65t | |||

| Power (kw) | 357.62kw(not including generator set power) | |||

Solution

Thank you for your interest in Vanguard Machinery. If you want to know more about our crushers and industrial

grinding equipment.

Contact us now to find out what we can do for you!

Copyright © Zhengzhou VANGUARD Machinery Technology Co., Ltd.