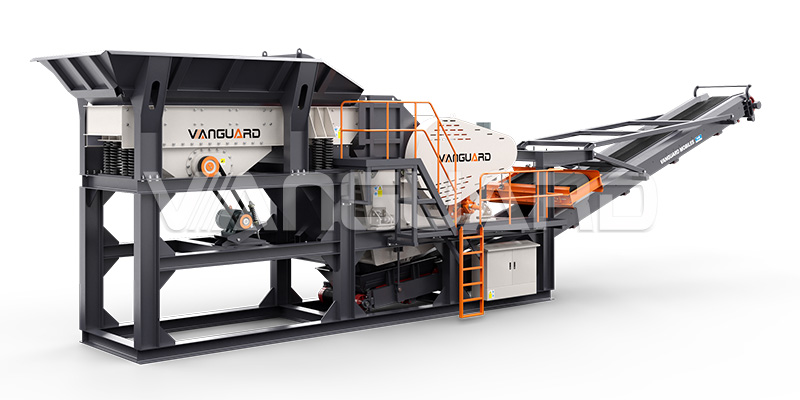

MBP Series Jaw Crushing Plant

Capacity:95-350T/H

Application:Suitable for medium-hard natural stone and recycled aggregate of construction waste, etc.

Video Case

Capacity:200 t/h

Max. Input size: ≤600mm

Output size: ≤40 mm

Processing materials: diamond mine

Project advantages: The mobile crushing plant production line has a modular design and stable operation. Each model can be used alone in one stage of crushing, or it can be used in conjunction with other mobile crushing and screening plant and other equipment to achieve two-stage, three-stage or four-stage crushing, meeting a variety of crushing and screening needs.

Overview

MBP series jaw crushing plant uses the optimized frame structure and movable jaw design, mainly used for the coarse crushing of minerals and rocks. According to the different production capacity, it can be designed and matched with different specifications of the feeder, jaw crusher, belt conveyor and other modular structural parts.

Features

The frame is divided into welding type and assembled type. The small and medium-sized specifications generally adopt the welding type, and the large-scale specifications generally adopt the assembled type.

The V-shaped crushing cavity design is adopted, the toggle plate has a large inclination angle and a large stroke. Compared with the traditional PE series jaw crusher, it has the larger feeding particle size, the higher output, more uniform the particle size, and reduced the jaw plate wear.

The integral cast steel bearing seat structure ensures complete coordination with the frame, which makes the bearing run more smoothly and avoids unnecessary radial load on the bearing during the tightening process of the combined bearing seat.

The crusher is fixed by a special rubber shock absorption device, which effectively absorbs the peak vibration of the equipment and allows the vertical and longitudinal displacement of the crusher, thereby reducing the impact on the foundation.

Specifications - Technical Data

| Project | Device Name | Models and Specifications | Power (kW) | Amount | |

|

C106 Jaw Crusher + ZSW4211 Feeder |

feeding machine | equipment | ZSW4211 | / | 1 |

| motor | Standard | 15 | 1 | ||

| jaw crusher | equipment | C106 | / | 1 | |

| triangle belt | Standard | / | 10 | ||

| motor | Standard | 110 | 1 | ||

| Modular steel structure | Standard | / | 1 | ||

| main conveyor | Specification | B1000*12m | 11 | 1 | |

| drive mode | electric drum drive | / | 1 | ||

| magnetic separator | Specification | RCYQ-10 | 2.2 | 1 | |

| drive mode | reducer | / | 1 | ||

| Electrical System | Electric control cabinet | Feeder motor variable frequency speed regulation, host soft start, electrical components Chint | / | 1 set | |

| / | 1 set | ||||

| Hydraulic Pumps, Valves, Stations and Tubing Accessories | / | 1 set | |||

| Total power 138.2KW | |||||

| Project | Device Name | Models and Specifications | Power (kW) | Amount | |

|

C80 Jaw Crusher + ZSW3090 Feeder |

feeding machine | equipment | ZSW3090 | / | 1 |

| motor | Standard | 11 | 1 | ||

| jaw crusher | equipment | C80 | / | 1 | |

| triangle belt | Standard | / | 5 | ||

| motor | Standard | 55 | 1 | ||

| Modular steel structure | Standard | / | 1 | ||

| main conveyor | Specification | B650*12m | 5.5 | 1 | |

| drive mode | electric drum drive | / | 1 | ||

| magnetic separator | Specification | RCYQ-6.5 | 1.5 | 1 | |

| drive mode | reducer | / | 1 | ||

| Electrical System | Electric control cabinet | Feeder motor variable frequency speed regulation, host soft start, electrical components Chint | / | 1 set | |

| / | 1 set | ||||

| Hydraulic Pumps, Valves, Stations and Tubing Accessories | / | 1 set | |||

| Total power 73KW | |||||

| Project | Device Name | Models and Specifications | Power (kW) | Amount | |

|

C96 Jaw Crusher + ZSW3896 Feeder |

feeding machine | equipment | ZSW3896 | / | 1 |

| motor | Standard | 11 | 1 | ||

| jaw crusher | equipment | C96 | / | 1 | |

| triangle belt | Standard | / | 5 | ||

| motor | Standard | 75 | 1 | ||

| Modular steel structure | Standard | / | 1 | ||

| main conveyor | Specification | B800 * 12m | 7.5 | 1 | |

| drive mode | electric drum drive | / | 1 | ||

| magnetic separator | Specification | RCYQ-8 | 1.5 | 1 | |

| drive mode | reducer | / | 1 | ||

| Electrical System | Electric control cabinet | Feeder motor variable frequency speed regulation, host soft start, electrical components Chint | / | 1 set | |

| / | 1 set | ||||

| Hydraulic Pumps, Valves, Stations and Tubing Accessories | / | 1 set | |||

| Total power 90KW | |||||

Solution

Thank you for your interest in Vanguard Machinery. If you want to know more about our crushers and industrial

grinding equipment.

Contact us now to find out what we can do for you!

Copyright © Zhengzhou VANGUARD Machinery Technology Co., Ltd.