The crushing wall and the concave are important components of the cone crusher. The material is directly rolled and crushed in the crushing chamber composed of the two. Therefore, the wear of the crushing wall and the concave is relatively serious. In general, the service life of the crushing wall is longer, and the service life of the concave is relatively short, usually 5-6 months.

Factors Influencing service life of crushing wall and concave

1. Stone powder content and stone humidity

If the stone powder content and humidity of the material are high, the material is easy to adhere to the crushing wall and the concave, which will greatly reduce the production efficiency and will corrode the crushing wall and the concave to reduce its service life. Therefore, measures can be taken before crushing, such as sieving, drying, etc., to avoid excessive fine powder and high water content of the material.

2. The hardness and particle size of the material

The hardness of the material will also affect the service life of the crushing wall and the concave. Generally, the higher the hardness of the material, the harder it is to break, the greater the impact load on the crushing wall and the concave during production, and the corresponding shortening of the service life. When the same hardness of the ore, the larger the particle size of the ore entering the crushing cavity, the more serious the wear of the liner and the shorter the service life.

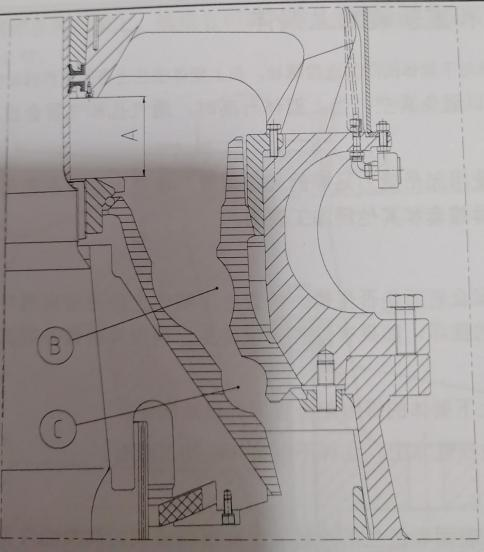

In addition, the uneven particle size of the feed will also affect the wear position of the liner, resulting in uneven wear of the liner. If the size of all the stones fed in is close to the maximum size, the crushing will be concentrated on the upper part of the crushing chamber, and an annular groove will be formed around the upper part of the entire crushing chamber (B in the figure below). If most of the stones are fine stones, they will be concentrated in the lower part of the crushing chamber, and the result shown in C in the figure below will be formed.

Both will cause the actual operating power of the cone crusher to be low, and the liner will wear irregularly, resulting in a shortened service life of the liner and increased production costs.

3. Feeding method

The feeding method of the cone crusher will also affect the service life of the crushing wall and the concave.

The material must be fed in the middle of the feeding tray, and it is not allowed to feed the material directly into the crushing cavity, which makes the liner wear unevenly in order to prevent the crusher from overloading. Correct feeding requirements: The material is evenly dispersed in the crushing chamber through the feeding tray, and segregation is not allowed. And the crushing cavity must be filled with material, but the material should not be too much, otherwise, it will cause blockage. An incorrect feeding method will reduce the use efficiency of the liner, increase energy loss (that is, large bearing load), reduce production capacity, and weaken fine crushing ability with poor stone forming.

In addition, the installation of the feeding device will also affect the feeding. If the installation is not proper, it will also lead to uneven feeding, which will cause excessive force on one side of the crushing wall and concave and increase the cutting wear of the material on it. The liner is seriously damaged and the service life will be greatly reduced.

4. Own quality

The quality of the crushing wall and the concave of the cone crusher is also particularly important. The quality directly affects the production capacity and life of the crusher. Therefore, the design of the crushing wall and the concave should use reasonable materials, such as stamping resistance, earthquake resistance, and toughness. Strong iron and steel materials, casting defects such as cracks and affecting performance are not allowed to ensure the stable operation of the crusher.

Vanguard Machinery has a complete supply system of after-sales accessories. We provide you with all accessories of mining machinery and technical equipment produced by our company. The complete models, reliable performance, stability and durability, so as to ensure that the replacement needs of customers can be met the first time, and reduce the time of downtime and maintenance of customers.