The belt conveyor is a commonly used material conveying equipment. It drives the conveyor belt to move through the transmission roller, so as to transport the material from one place to another. It has a simple structure and is easy to maintain. It is widely used in mines, ports, electric power, the chemical industry, Metallurgy and other industries.

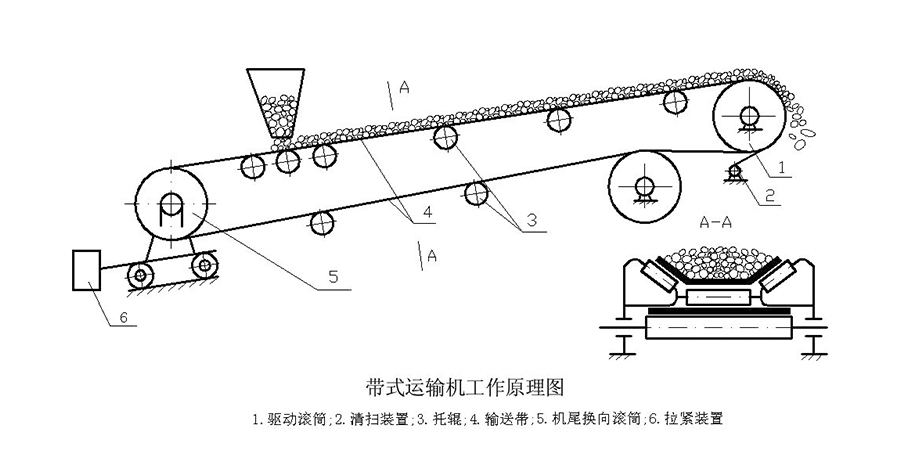

The belt conveyor is mainly composed of driving rollers, cleaning devices, idlers, conveyor belts, tail reversing rollers, and tensioning devices. These components work together to ensure the efficient and stable operation of the belt conveyor.

1. Driving roller: The driving roller is a key component that drives the movement of the conveyor belt, and it is located at the head of the conveyor belt. It is usually composed of the motor, reducer, transmission, bearing and roller, etc. The motor and the reducer are used to provide power, and the transmission transmits the power to the transmission belt, thereby driving the movement of the entire conveyor belt system.

2. Cleaning device: The cleaning device is used to clean up the debris, dust and accumulation on the conveyor belt to ensure the normal operation of the conveyor belt and the smooth transmission of materials.

3. Idler: The idler is an important part of supporting and guiding the conveyor belt. It is located at the bottom or both sides of the conveyor belt and plays a role in supporting and reducing the friction between the belt conveyor and the conveyor belt.

4. Conveyor belt: The conveyor belt is the core component of the belt conveyor, used to carry and transport materials. It is usually made of materials such as multi-layer fabric or metal chip layer, which has good wear resistance and stretching properties.

5. Tail reversing roller: 5. Tail reversing roller: The tail reversing roller is used to change the direction of the conveyor belt. It is usually located at the end of the conveyor belt as the tail device of the conveyor belt, and its working principle is to generate enough friction on the conveyor belt through the contact between the reversing roller and the conveyor belt, so as to guide the conveyor belt to the desired direction. Tail diverter pulleys are critical to smooth, reliable conveyor belt operation.

6. Tensioning device: The tensioning device is used to adjust and maintain the proper tension of the conveyor belt to ensure the normal operation of the conveyor belt during operation.

The belt conveyor has the following characteristics:

Efficient and reliable: The belt conveyor can continuously and efficiently transport a large amount of materials, and can meet the needs of long-distance, large-volume, and high-speed transportation.

Long transportation distance: The belt conveyor is suitable for long-distance material transportation, which can stably transport materials between different locations, reducing manual handling and transportation costs.

Strong adaptability: The belt conveyor is suitable for conveying different types of materials, whether it is bulk materials or packaged materials, the material and structure of the conveyor belt can be adjusted to meet different conveying requirements.

Environmental protection and energy saving: The belt conveyor adopts an electric drive, which has the characteristics of low energy consumption and environmental protection compared with other conveying equipment such as screw conveyors and bucket elevators.

The belt conveyor may encounter some common faults during use. The following are some typical faults and their solutions. The actual situation may vary due to the equipment model, working environment and material characteristics. For details, please consult professional technicians.

1. The conveyor belt breaks or falls off

Common causes include overloading, material buildup, belt aging, etc. The treatment method is to stop the operation of the conveyor, repair or replace the damaged conveyor belt after ensuring safety, and eliminate the cause of breakage or shedding.

2. Roller failure

The idler shaft may be broken, stuck or bearing damaged. The treatment method is to check the idler roller, replace the worn or damaged idler roller, and ensure that the idler roller can rotate freely to ensure the normal operation of the conveyor belt.

3. Drive system failure

Including motor failure, reducer damage, etc. The treatment method is to check the motor, reducer and transmission parts, repair or replace the faulty equipment, and ensure the normal operation of the transmission system.

4.Failure of the cleaning device

The scraper cleaner or brush cleaner may be worn, poorly connected or invalid. Treatment methods include replacing worn cleaning devices, adjusting the contact force of the cleaning device, and ensuring that the cleaning device can effectively remove materials and impurities.

5.Tension control failure

The failure of the tensioning device causes the conveyor belt to be too loose or too tight. The treatment method is to check the tensioning device and adjust or replace the tensioning device to ensure proper tension, so as to prevent the conveyor belt from slipping or being too tight to cause failure.

6.Offset and deflection

The conveyor belt may be offset or deflected, resulting in the accumulation or overflow of materials. Treatment methods include adjusting the centering device of the conveyor belt, repairing or replacing the offset idler roller, and ensuring that the conveyor belt maintains a stable and centered position during operation.

7.Frequent power failure or shutdown:

This may be due to electrical control system problems, safety protection device failure, or unstable power supply. Treatment methods include checking the electrical system, ensuring that safety protection devices are working properly, resolving power supply problems, and restoring normal electrical operation.

It should be noted that when using a belt conveyor, reasonable selection should be made according to the nature of the material, conveying distance, conveying capacity and other factors to ensure the safe and stable operation of the equipment. In addition, regularly maintain the equipment, check the wear of the conveyor belt, and replace damaged parts in time to extend the service life of the equipment.

As a professional mining machinery manufacturer, Vanguard Machinery focuses on product quality and technological innovation, adopts high-quality materials and manufacturing processes, and provides customers with customized and personalized solutions.