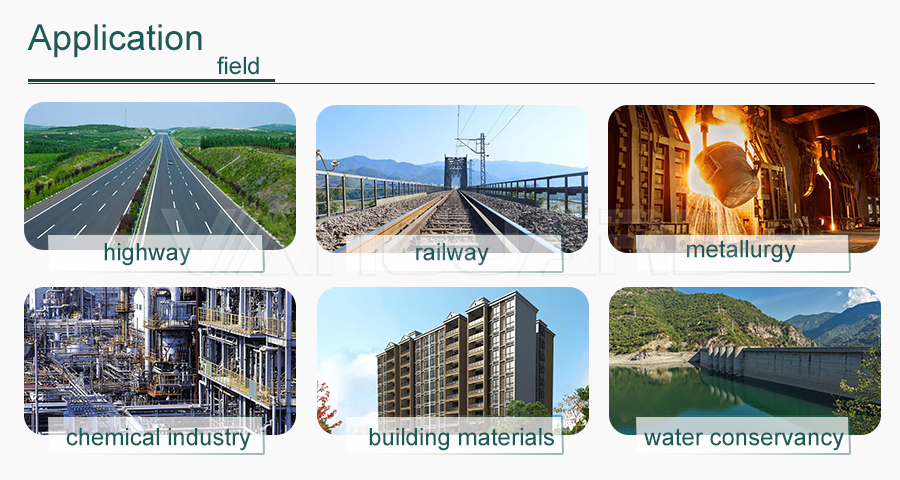

The mobile crushing plant is mainly used for the processing of metallurgy, the chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of mobile stones such as highways, railways, and hydropower projects. During use, the mobile crushing plant also needs regular repair and maintenance to ensure its normal operation and extend its service life.

First of all, before using the mobile crushing plant, you need to understand its basic structure and working principle, master the operating procedures and precautions. During normal use, the operation procedures shall be strictly followed to ensure the normal operation and safe use of the equipment.

1. Composition and principle

The mobile crushing plant is composed of feeder, crusher, vibrating screen, conveyor and electrical control system. The vibrating feeder is driven by a motor, and the raw materials are evenly transported to the crusher. The crusher crushes the material through the rotating hammer hitting and crushing, the crushed material is sieved, and then the finished product will be obtained. The whole process is controlled automatically by the electric control cabinet, which can realize automatic production line operation.

2. Operation process

Before starting the equipment, it is necessary to check whether the components of the equipment are in good condition, especially whether the hammer head of the crusher is worn, and whether the belt of the conveyor is loose; When starting the equipment, it should be operated according to the specified steps, first start the vibrating feeder, conveyor, and then start the crusher and the vibrating screen to ensure the normal operation of the equipment; In the production process, the accumulated materials and sundries inside the equipment shall be cleaned in time to avoid damage to the equipment; During the shutdown, the vibrating screen and crusher shall be stopped first, and then the conveyor and the vibrating feeder shall be stopped according to the specified procedures.

3. Precautions

Produce in strict accordance with the load capacity of the equipment, and do not overload the equipment to avoid damage to the equipment; Regularly replace wearing parts, such as the hammerhead of the crusher and the screen to ensure the normal operation and production efficiency of the equipment; In case of equipment failure or abnormal situation, the equipment shall be shut down in time to eliminate the fault, so as to avoid the expansion of the fault and greater damage to the equipment.

Secondly, mobile crushing plant maintenance is the key to prolonging its life. During the use of equipment, regular maintenance including the cleaning of equipment, lubrication of equipment, and fastening to ensure that the normal operation and the performance of each component of the equipment are not affected.

1. Clean

Clean the mobile crushing plant regularly, including the machine surface, oil circuit, and hydraulic oil tank to ensure that the equipment is clean and hygienic, and prevent dust and debris from entering the interior of the equipment;

2. Lubrication

Lubrication of the mobile crushing plant of each component regularly to ensure that the friction between the components is not too large when the equipment is running at high speed, reduce wear and extend the service life;

3.Timely repair and replacement of damaged parts of equipment

If you find equipment failure or excessive component wear, you should contact the after-sales service for maintenance or replacement parts. This not only ensures the normal operation of the equipment but also effectively extends the service life of the equipment.

(1). Replace the filter element:All kinds of hydraulic systems in the mobile crushing plant need to regularly replace the filter element to avoid debris entering the equipment and affecting the normal operation of the equipment;

(2). Lubricating oil replacement:All kinds of mobile crushing plant hydraulic systems and engines need to be replaced regularly with lubricating oil to ensure that the friction between the components will not be too large when the equipment is running at high speed and reduce wear;

(3). Adjust belt tension:the mobile crushing plant belt needs to be checked regularly and adjust the tension to ensure that the belt will not be loose or too tight when the equipment is running, to avoid equipment failure at work;

(4). Check the electrical system:The electrical system of the mobile crushing plant needs to be checked regularly to ensure that the electrical equipment operates normally and avoids short circuits or other faults;

(5). Replace the wearing parts:Mobile crushing plant wearing parts, including the crusher hammer, belt and screen, these parts wear more during use, need to be replaced regularly to ensure the normal operation of the equipment.

How to maintain the mobile crushing plant?

Maintenance regularly:The mobile crushing plant shall be maintained regularly and maintenance in accordance with the requirements of the instruction manual and the maintenance manual.

Refueling:The mobile crushing plant constantly needs to add fuel, lubricating oil and hydraulic oil during operation to ensure the normal operation of the equipment.

Keep dry:The mobile crushing plant equipment needs to be kept dry, ventilated, and dust-free to avoid moisture and direct sunlight inside the equipment, affecting the normal service life of the equipment.

Code of Practice:Mobile crushing plant operators need to operate in accordance with the operating instructions and safety to avoid equipment failure due to improper operation.

Check regularly:The mobile crushing plant needs to be checked regularly, including all parts of the equipment, equipment oil circuit and hydraulic oil tank to ensure that the equipment is in good working condition.

Timely maintenance:In case of equipment failure or abnormal conditions, it is necessary to timely repair or replace relevant parts in order to assure the normal use of the equipment.

In short, the repair and maintenance of the mobile crushing plant is the key to the normal operation and extended service life of the equipment. It requires equipment operators and maintenance personnel to pay attention to the safety scientific and standardized operation methods, operate and maintain in strict accordance with the operating procedures, and timely repair and replace damaged parts to extend the service life of the device.

Vanguard Machinery Tech is a professional manufacturer of mobile crushing plants, mining machinery and other equipment, can provide customers with high-quality mining machinery solutions, after-sales personnel with professional technical knowledge and rich practical experience can provide customers with high-efficient professional, perfect service including equipment, debugging, training and maintenance. The company also has advanced production equipment and a management system, which can ensure the quality of production and delivery time of equipment, so that customers can quickly profit.