Hammer crusher and jaw crusher are common mining equipment, both have applicable occasions and characteristics, choose which crusher should be based on the actual situation to decide, such as what kind of materials need to be crushed, the requirements of the discharge size and other factors, and in some cases, you can also use two crushers combined to achieve the better crushing effect.

Hammer crusher comparison with the jaw crusher:

1.Scope of application:

The hammer crusher is suitable for crushing materials with high hardness and large particle size, such as limestone, gypsum, coal, basalt, etc. The hammer crusher, high-efficient, energy-saving and environmental protection, is widely used in construction, metallurgy, chemical industry cement, ceramics and other industries.

The jaw crusher is suitable for crushing materials with low hardness and small particle size, such as ore, coal and construction waste. Jaw crusher is characterized by a simple structure, convenient maintenance, and large reduction ratio, which is widely used in mining, metallurgy, construction, highway, railway and other industries.

2. Composition and working principle:

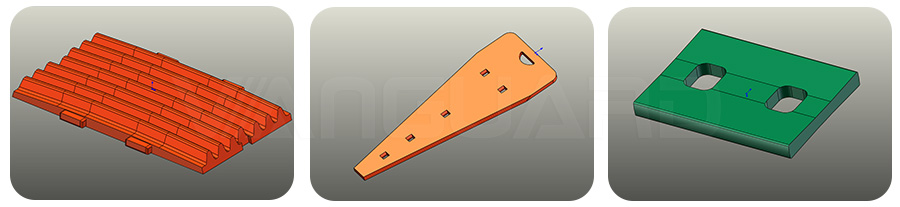

The hammer crusher is mainly composed of rotor, hammerhead, impact plate, sieve plate and transmission device, etc. The crushing principle is to use the high-speed rotation of the rotor and the repeated hammer collision to crush the material into the required size of particles. When the material enters the crusher, it is crushed by hammer, impact, shearing and friction and other ways. The material is crushed into the required particle size and discharged through the sieve plate after many collisions and crushing under the impact force.

The jaw crusher is mainly composed of rack, eccentric shaft, rotating part, crushing cavity, safety device and discharge port adjustment device with a relatively simple structure and relatively convenient operation and maintenance. The jaw crusher's crushing principle is to use the opening and closing movement of the jaw plate to crush the material. The upper jaw plate and the lower jaw plate are connected with the connecting rod mechanism through the eccentric shaft. With the rotation of the eccentric shaft and the action of the connecting rod mechanism, the upper and lower jaw plates do the periodic movement. When the lower jaw moves upward, the material is clamped for crushing, and when the lower jaw moves downward, the crushed material is released. When the upper and lower jaw plates are closed, the material is compressed and squeezed. The material is released when the upper and lower jaws are far away, so that a crushing process is completed. After crushing for several times, the material achieves the required crushing effect, and the crushed material is discharged through the discharge port.

3.Wearable parts:

The main wear parts of the hammer crusher are the hammerhead, liner, impact plate, and grate bar. The wearing parts of the jaw crusher are mainly the movable jaw plate, toggle plate and side guard plate. When using the crusher, the wear of the wearing parts should be checked regularly and replaced in time.

4.Adjustment mode of the discharge port:

The adjustment of the discharge opening hammer crusher is to make the crushing effect of the crusher more ideal, and at the same time to ensure safety performance of the crusher. The discharge opening adjustment hammer crusher usually controls discharge size through clearance adjustment. The following is steps to adjust discharge port:

(1).Turn on the power, start the crusher to make it work normally;

(2).Place a discharge hopper under the discharge port of the crusher, adjust the discharge port of the crusher to align with the center of the discharge hopper, and adjust the height of the discharge port to make it the same height as the discharge hopper;

(3).Adjust the discharge opening by shortening or extending the adjustment rod until the desired particle size and discharge opening are achieved;

(4).Check whether there are foreign objects or broken materials at the discharge port of the crusher, and clean up if necessary;

(5).Adjust the feeding amount of the crusher to match the crushing capacity of the crusher to avoid overload or shortage;

(6).Monitor the operating status of the crusher, and adjust the position and height of the discharge port in time to maintain its stability.

The adjustment of the discharge port jaw crusher refers to the adjustment of the size of the discharge port of the crusher to meet the crushing requirements of different materials. Adjusting the size of the discharge port can change the residence time and crushing degree of the material in the crushing cavity, thus affecting the output and efficiency of the crusher.

Usually, the discharge port of the jaw crusher can be realized by adjusting the adjusting backing plate at the lower part of the crusher, and the position of the adjusting backing plate can be adjusted manually or hydraulically. European type jaw crusher wedge block the adjustment, through the position of the adjusting wedge to control the up and down movement of the jaw plate, so as to adjust the size and particle size of the discharge port, this adjustment method is relatively simple, flexible, and can be adjusted in real-time in the production process.

It should be noted that when adjusting the discharge port, it should be adjusted according to the crushing requirements of different materials, so as to avoid affecting the crushing efficiency and output of the crusher due to too large or too small discharge port.

Vanguard Machinery is a company specializing in the manufacture of mining and equipment. The company has strong strength and excellent technology, has a group of professional technicians and modern production equipment, has established a perfect quality service and control system, and constantly improves the high capacity and service quality, can provide customers with better experience and value.